Currently Empty: $0.00

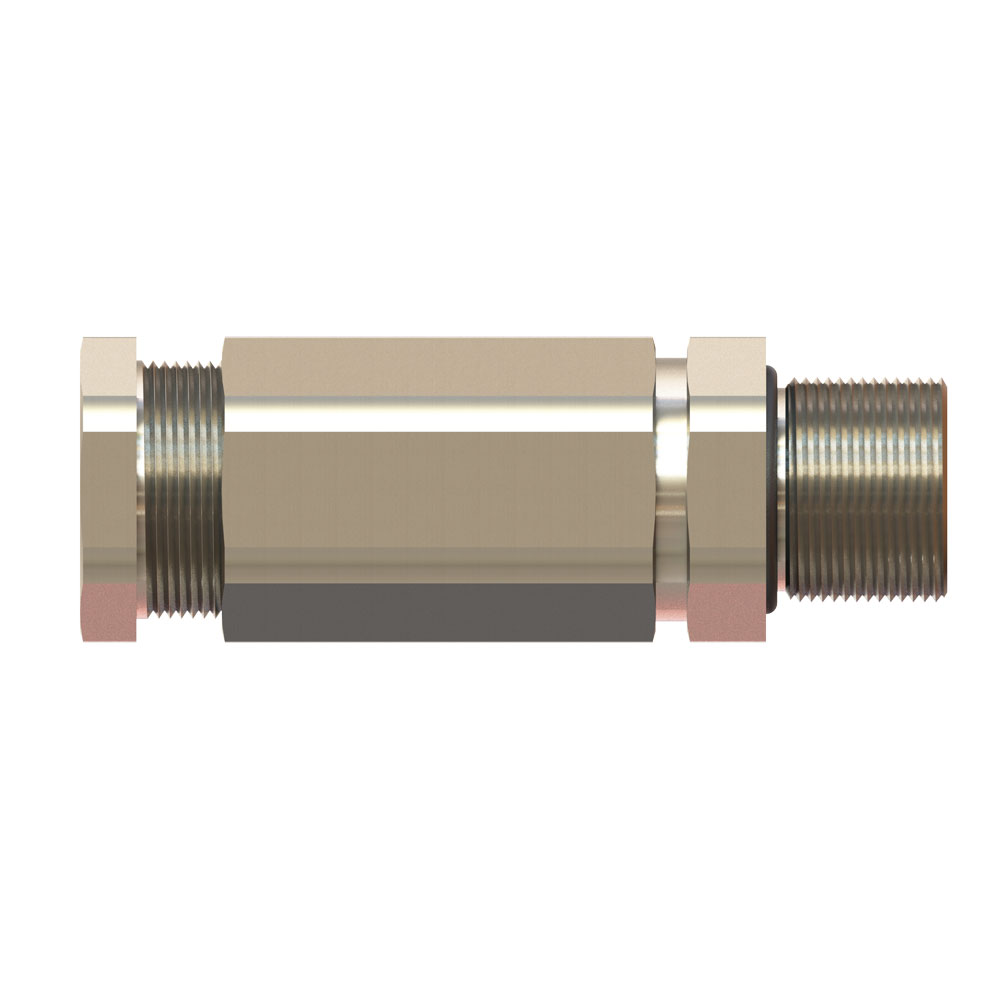

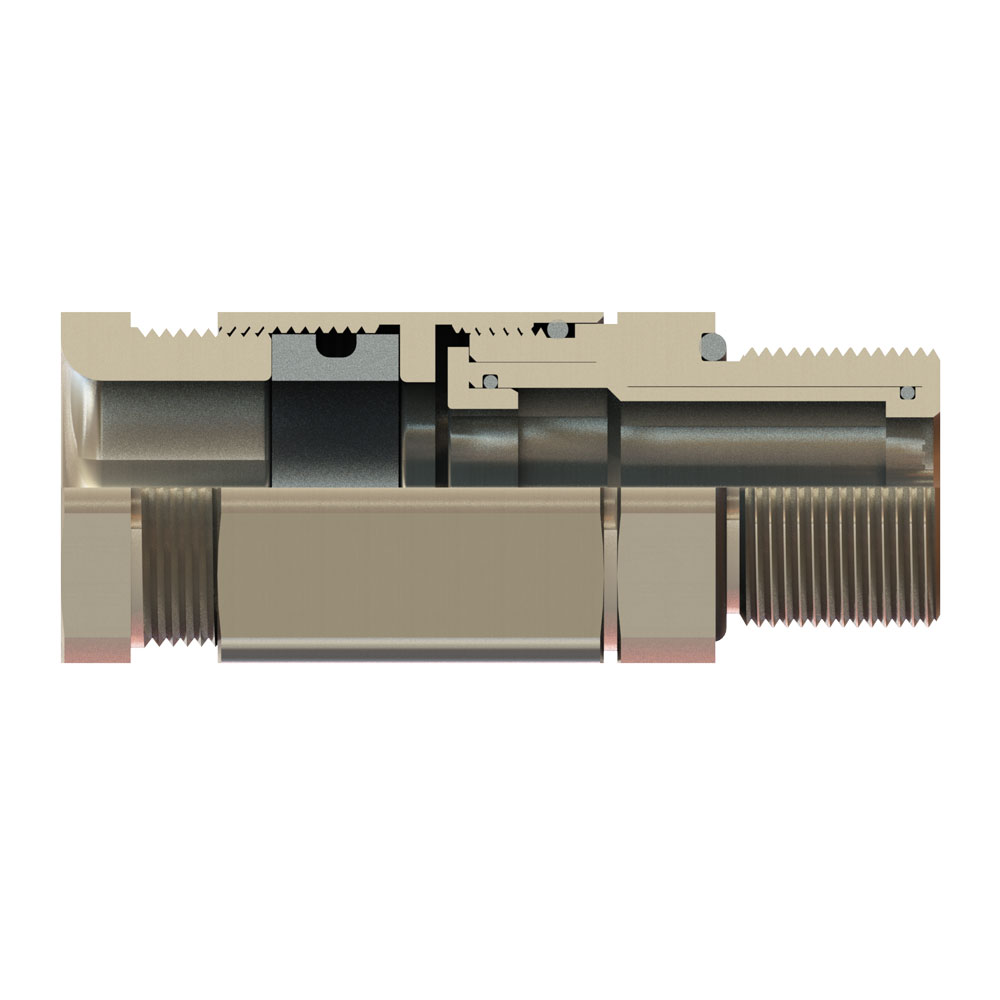

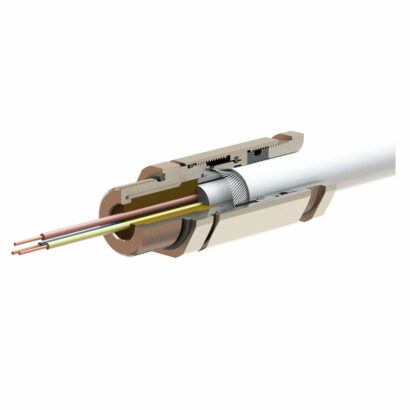

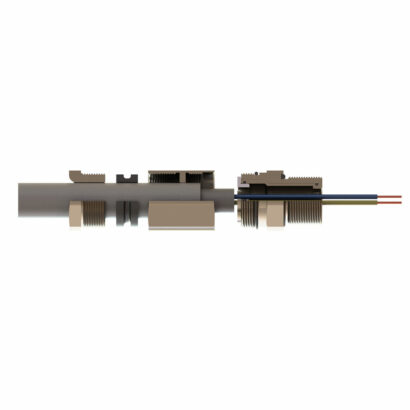

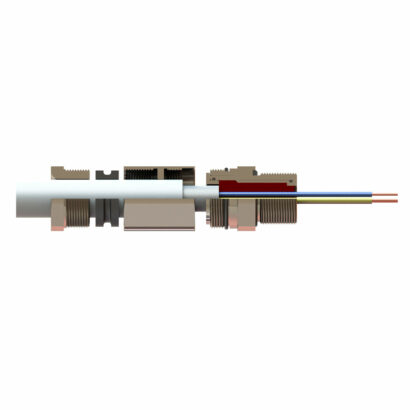

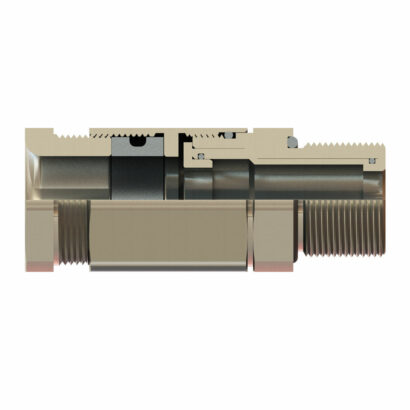

Centaurus ARMOURED

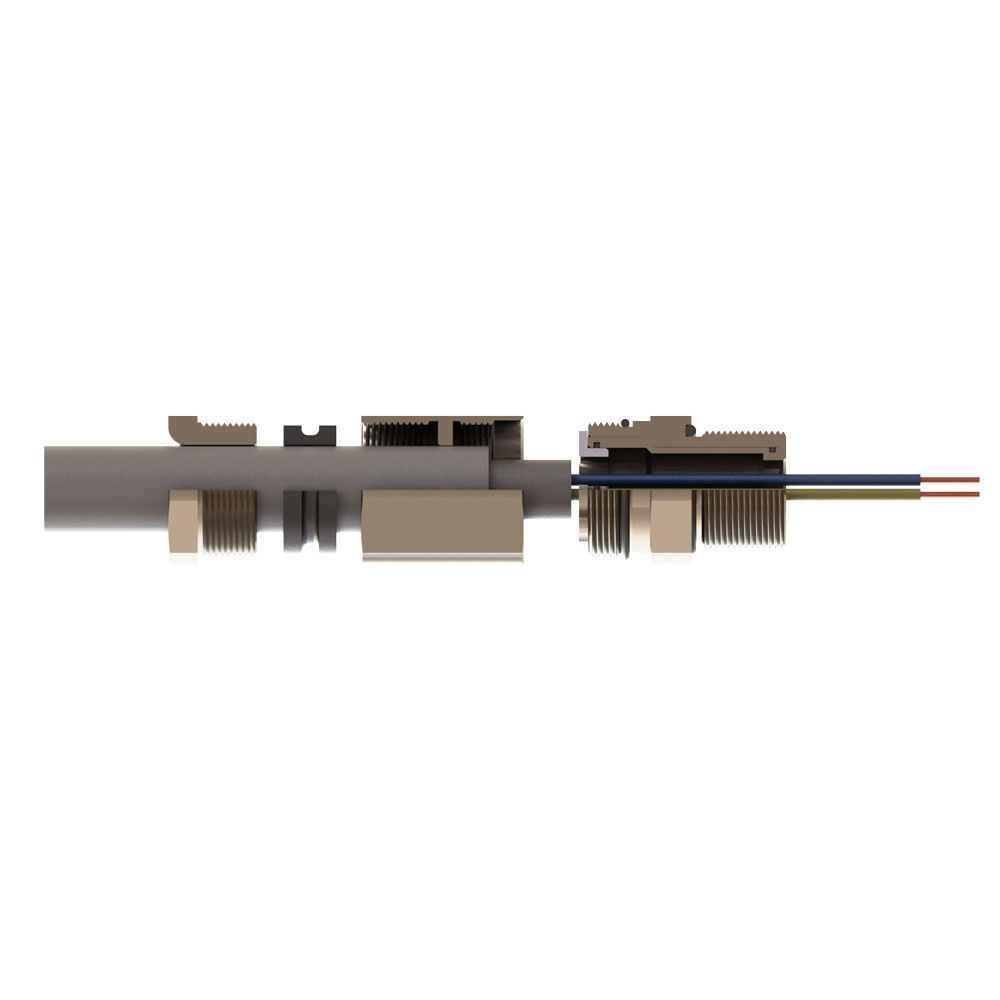

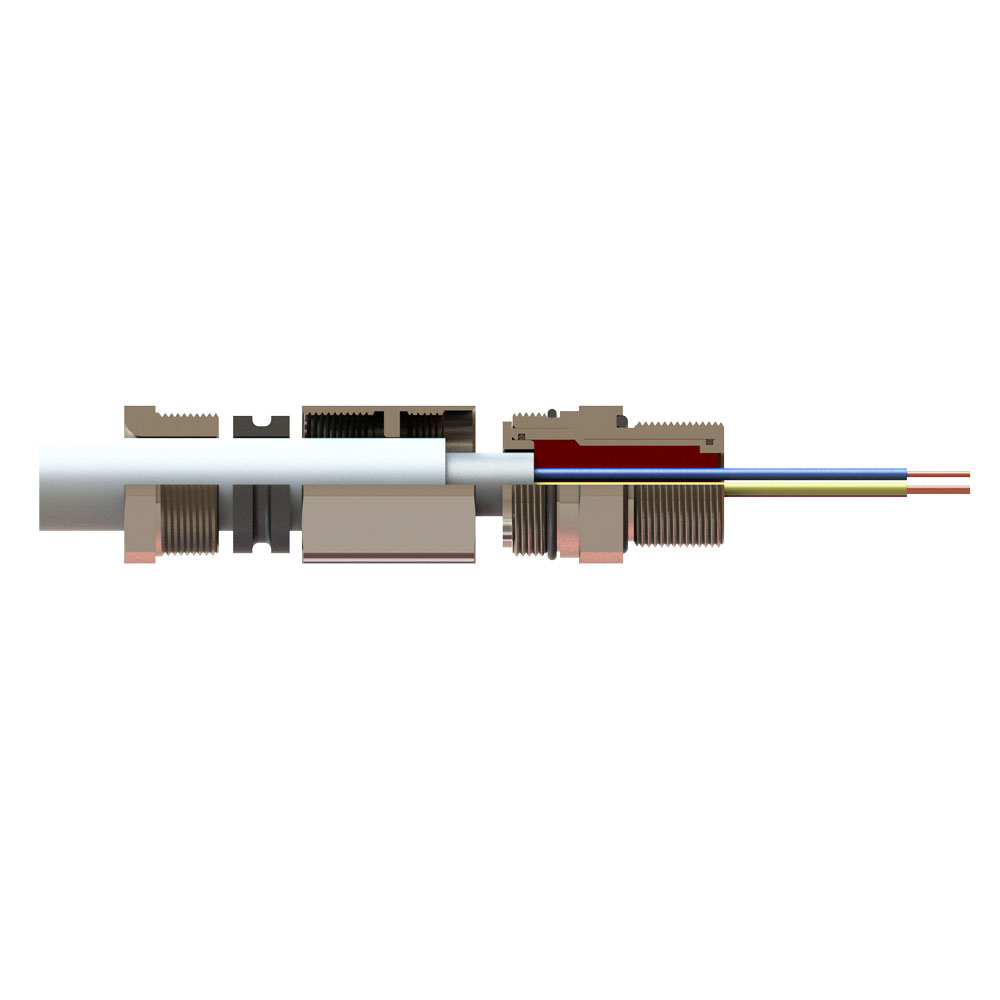

- For applications in explosive environments.

- For Group I (Mining) - Ex-d and Ex-d/e.

- Special design for mining applications.

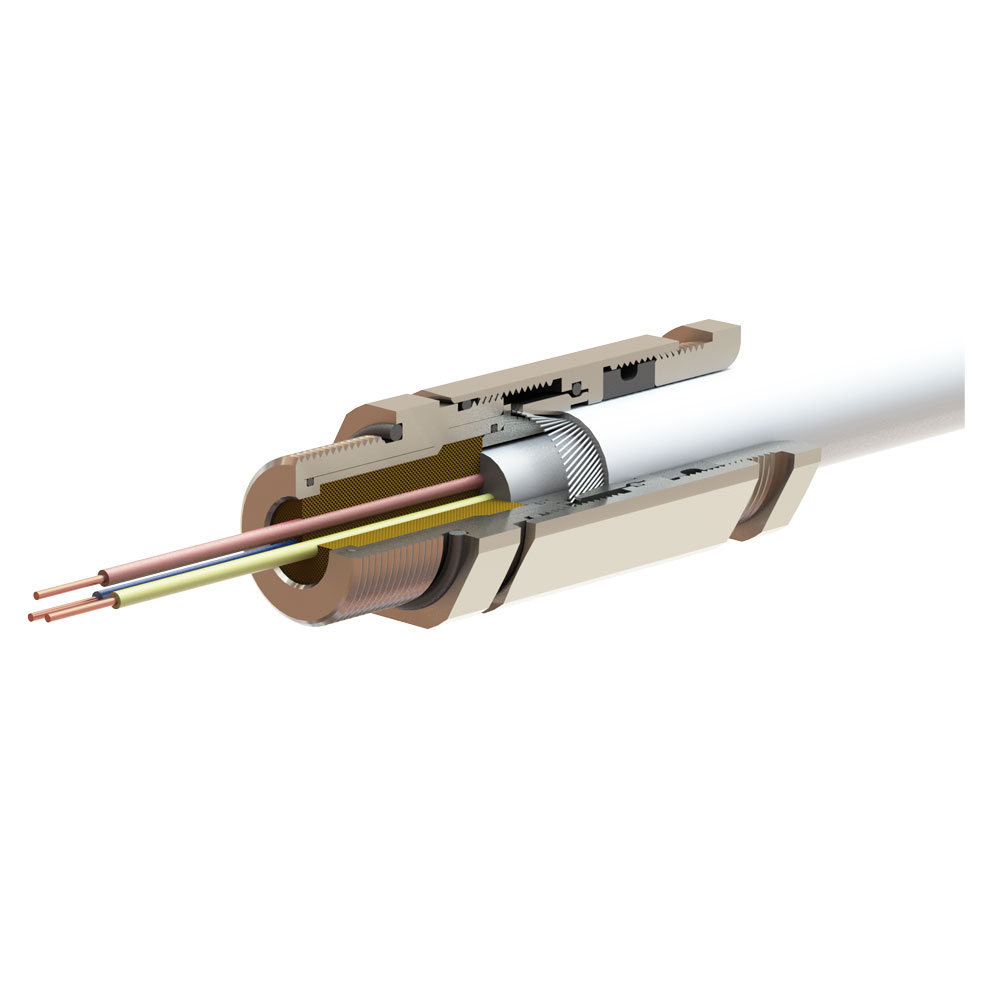

- Barrier seal for perfect sealing.

- Can be used with intrinsically safe circuits.

- High quality strain relief and sealing, reliable performance for mining hazardous area applications.

- Up-to-date international approvals.

Barrier Cable Glands for All Types of Armoured Cables

Mining, Gas, Dust applications

Ex I M2 – Ex db IMb Ex eb IMb

CERTIFICATES

Categories: Armoured Cables, Barrier Glands

Delivery and return

Delivery and return

Shipping Information

Shipping Information

Composition and care

Composition and care

Description

| Suitable for use in | Group I, Group II, Group III |

| Equipment Marking | EX I M2 Ex db I Mb, Ex eb I Mb EX II 2GD Ex db IIC Gb, Ex eb IIC Gb, Ex tb IIIC Db |

| Ingress Protection Rating | IP66, IP68 – 5 Bar, 30 min |

| Type Rating | TYPE 4X |

| Cable Gland Material | Brass, Brass Nickel Plated, Stainless Steel |

| Seal Material | Silicone |

| Operating Temperature | Silicone: -60°C to +100°C |

| Thread Type | Metric, NPT |

| Other thread types available upon request. | |

| Cable Type | Armoured (SWA, AWA, STA), Braided, Shielded |

| Accessories | Lock nuts, Gaskets (Washers), Serrated Washers, Shrouds, Earth tags |

| Remarks | Accessories must be ordered separately. O-ring available in Metric outer threads. |

| Product Certificates | |

| ATEX Approval | CESI 17 ATEX 007X |

| ATEX standards | EN 60079-0, 1, 7, 31 |

| IECEx Approval | IECEx CES 17.0029X |

| IECEx standards | IEC 60079-0, 1, 7, 31 |

| TR CU (EAC) | No TC RU C-TR.AA87.B.00941 |

| TR CU standards | ГОСТ 31610.0; ГОСТ IEC 60079-1, 7, 31 |

| Marine Approval | TAE00003WU |

| UKCA | CML 22UKEX1185X |

Technical

Product Selection Table

Showing:

| Thread Type METRIC acc. to ISO 965-3 | |||||||||||

Outer Thread Size (Male) |

Clamping Range

Ø min – max mm |

Over Conductors

Ø max mm |

Armour Wire

Ø max mm |

Outer Thread Length

TL |

Spanner Width | Outer ØD mm |

max. HeightH mm |

Part Number |

Needed Barrier Compound Mixture Per Pcs. (g) |

||

| Cap

SW Cap mm |

Upper Body

SW Upper Body |

Lower Body

SW Lower Body |

|||||||||

| M20x1,5 | 3,0 – 8,5 | 9,5 | 1,0 | 16,0 | 25 | 25 | 25 | 27,0 | 63,5 | KBCTA1XSM | 7 |

| 6,0 -13,0 | 9,5 | 1,3 | 16,0 | 25 | 25 | 25 | 27,0 | 63,5 | KBCTA1SM | 7 | |

| 8,0 – 15,0 | 9,5 | 1,3 | 16,0 | 25 | 25 | 25 | 27,0 | 63,5 | KBCTA1M | 7 | |

| 13,5 – 21,0 | 12,0 | 1,3 | 16,0 | 30 | 30 | 30 | 33,0 | 65,0 | KBCTA1LM | 9 | |

| M25x1,5 | 8,0 – 15,0 | 9,5 | 1,3 | 16,0 | 25 | 25 | 30 | 33,0 | 63,5 | KBCTA2SM | 7 |

| 13,5 – 21,0 | 12,0 | 1,3 | 16,0 | 30 | 30 | 30 | 33,0 | 65,0 | KBCTA2M | 9 | |

| 18,0 – 27,0 | 15,0 | 1,6 | 16,0 | 40 | 40 | 40 | 44,5 | 72,5 | KBCTA2LM | 20 | |

| M32x1,5 | 18,0 – 27,0 | 15,0 | 1,6 | 16,0 | 40 | 40 | 40 | 44,5 | 72,5 | KBCTA3M | 20 |

| 23,0 – 33,0 | 21,5 | 1,6 | 16,0 | 43 | 43 | 43 | 47,0 | 74,5 | KBCTA3LM | 31 | |

| M40x1,5 | 23,0 – 33,0 | 21,5 | 1,6 | 16,0 | 43 | 43 | 45 | 50,0 | 74,5 | KBCTA4SM | 31 |

| 29,0 – 40,0 | 29,0 | 2,0 | 16,0 | 50 | 50 | 50 | 55,5 | 82,5 | KBCTA4M | 60 | |

| M50x1,5 | 29,0 – 40,0 | 29,0 | 2,0 | 16,0 | 50 | 50 | 55 | 61,0 | 82,5 | KBCTA5SM | 60 |

| 35,0 – 48,0 | 37,0 | 2,5 | 16,0 | 58 | 58 | 58 | 64,0 | 90,5 | KBCTA5M | 90 | |

| M63x1,5 | 35,0 – 48,0 | 37,0 | 2,5 | 20,0 | 58 | 58 | 68 | 75,0 | 90,5 | KBCTA6SM | 90 |

| 42,0 – 56,0 | 46,0 | 2,5 | 20,0 | 75 | 75 | 75 | 83,0 | 120,0 | KBCTA6M | 193 | |

| M75x1,5 | 42,0 – 56,0 | 46,0 | 2,5 | 20,0 | 75 | 75 | 80 | 89,0 | 120,0 | KBCTA7SM | 193 |

| 54,0 – 70,0 | 58,0 | 3,2 | 20,0 | 100 | 100 | 100 | 110,5 | 126,0 | KBCTA7M | 337 | |

| M90x1,5 | 54,0 – 70,0 | 58,0 | 3,2 | 20,0 | 100 | 100 | 100 | 110,5 | 126,0 | KBCTA8M | 337 |

| Thread Type NPT acc. to ANSI ASME B1.20.1 | |||||||||||

| Outer Thread Size (Male) |

Clamping Range

Ø min – max mm |

Over Conductors

Ø max mm |

Armour Wire

Ø max mm |

Outer Thread Length

TL |

Spanner Width | Outer Ø

D |

max. Height

H |

Part Number |

Needed Barrier Compound Mixture Per Pcs. (g) |

||

| Cap

SW Cap mm |

Upper Body

SW Upper Body |

Lower Body

SW Lower Body |

|||||||||

| NPT 1/2″ | 3,0 – 8,5 | 9,5 | 1,0 | 21,0 | 25 | 25 | 25 | 27,0 | 63,5 | KBCTA1XSN | 7 |

| 6,0 – 13,0 | 9,5 | 1,3 | 21,0 | 25 | 25 | 25 | 27,0 | 63,5 | KBCTA1SN | 7 | |

| 8,0 – 15,0 | 9,5 | 1,3 | 21,0 | 25 | 25 | 25 | 27,0 | 63,5 | KBCTA1N | 7 | |

| 13,5 – 21,0 | 12,0 | 1,3 | 21,0 | 30 | 30 | 30 | 33,0 | 65,0 | KBCTA1LN | 9 | |

| NPT 3/4″ | 8,0 – 15,0 | 9,5 | 1,3 | 21,0 | 25 | 25 | 30 | 33,0 | 63,5 | KBCTA2SN | 7 |

| 13,5 – 21,0 | 12,0 | 1,3 | 21,0 | 30 | 30 | 30 | 33,0 | 65,0 | KBCTA2N | 9 | |

| 18,0 – 27,0 | 15,0 | 1,6 | 21,0 | 40 | 40 | 40 | 44,5 | 72,5 | KBCTA2LN | 20 | |

| NPT 1″ | 18,0 – 27,0 | 15,0 | 1,6 | 26,0 | 40 | 40 | 40 | 44,5 | 72,5 | KBCTA3N | 20 |

| 23,0 – 33,0 | 21,5 | 1,6 | 26,0 | 43 | 43 | 43 | 47,0 | 74,5 | KBCTA3LN | 31 | |

| NPT 1 1/4″ | 23,0 – 33,0 | 21,5 | 1,6 | 28,0 | 43 | 43 | 45 | 50,0 | 74,5 | KBCTA4SN | 31 |

| 29,0 – 40,0 | 29,0 | 2,0 | 28,0 | 50 | 50 | 50 | 55,5 | 82,5 | KBCTA4N | 60 | |

| NPT 1 1/2″ | 29,0 – 40,0 | 29,0 | 2,0 | 28,0 | 50 | 50 | 55 | 61,0 | 82,5 | KBCTA5N | 60 |

| NPT 2″ | 35,0 – 48,0 | 37,0 | 2,5 | 28,0 | 58 | 58 | 65 | 72,0 | 90,5 | KBCTA6N | 90 |

| NPT 2 1/2″ | 42,0 – 56,0 | 46,0 | 2,5 | 41,0 | 75 | 75 | 80 | 89,0 | 120,0 | KBCTA7N | 193 |

| NPT 3″ | 54,0 – 70,0 | 58,0 | 3,2 | 43,0 | 100 | 100 | 100 | 110,5 | 126,0 | KBCTA8N | 337 |

| *Barrier compound is served as 50 g standard. | |||||||||||